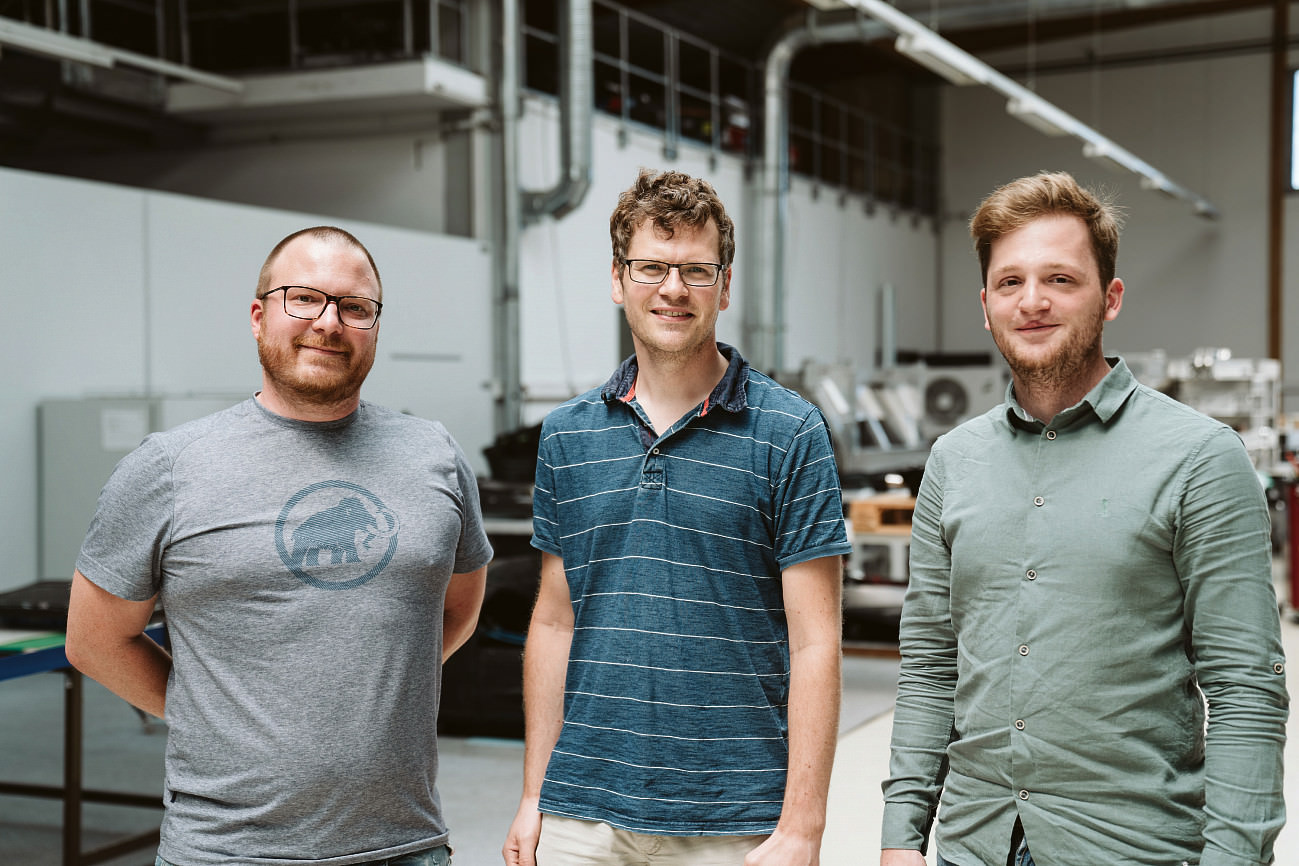

The Sion brings together the know-how of the people behind our vehicle development. One of them is Maximilian Seifert, who, as Director Vehicle Programs is significantly involved in the all the development steps and has been accompanying the Sion since its beginnings. In an interview with PR Manager Alexa Rauscher, he provides insights into the latest state of development, the consequences of the Corona crisis and his own personal highs and lows in over three years at Sono Motors.

Hi Max, the press is reporting that the corona crisis will have a drastic impact on the entire economy, including the automotive industry. Where do you see the Sion development team at the moment?

Right now, the safety and health of the team is the most important responsibility. That’s why we have taken a company-wide home-office approach. We see the same with all our partners. That means COVID-19 and the current situation will affect all of us, including Sono Motors and our future steps. What the current events will mean in detail for our development and prototyping, we can in the end only estimate in the coming weeks. However, since our day-to-day work is largely digitally organized, we are continuing to work with full commitment.

Does the current, difficult situation have an impact on the cooperation with our partners or has the shift to working in the home office also proved successful for vehicle development?

We have handled the situation really well so far, almost everything now runs via online meetings and phone calls. We, and also our partners are well prepared for such a situation thanks to the numerous possibilities to communicate digitally. Nevertheless, this is a challenge, because in the coming weeks the kick-offs, i.e. the starting signal for many of our projects, with our partners will take place. This also includes full-day workshops to discuss the current status, technical content, possible problems, and the next steps. In this process, personal meetings are therefore often almost indispensable. In order to lose as little time as possible, we have to find a way together with our partners to continue to work together in an optimal way. We are now trying to cover all this online.

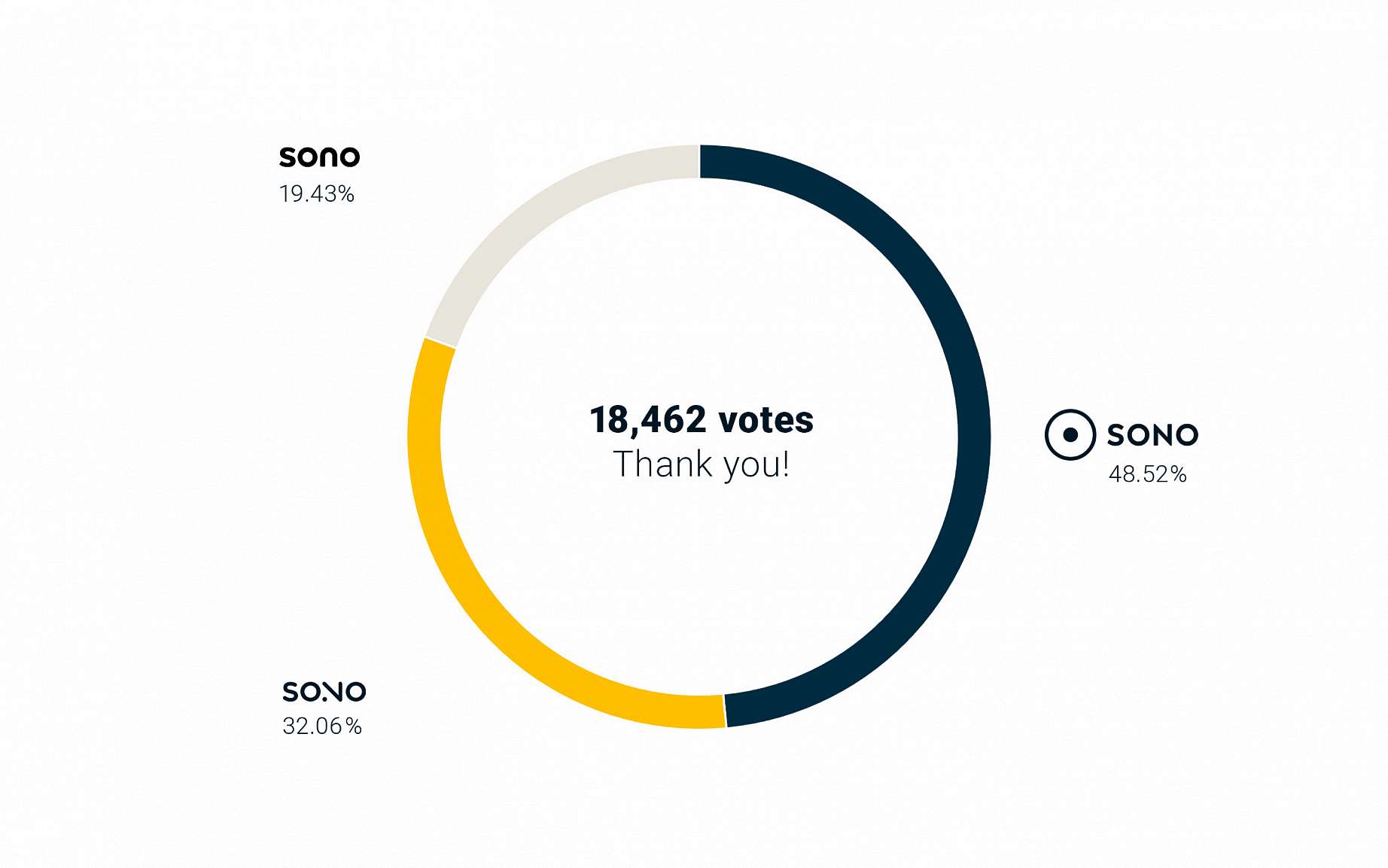

What has happened in the development team since the Community Funding Campaign was completed? Can you give us an insight?

A lot has already happened in different areas. Most importantly, the Community Funding Campaign has once again shown how much we as a team at Sono Motors stand together, along with our community. A large part of the development team provided massive support to other departments during the campaign. Even in the first weeks after the campaign, during which an incredible number of people contacted us by phone and email with their questions or suggestions. This means that we actually had to get all the engineers back into the development team and we had to re-form ourselves as a team in the vehicle development department. As soon as it was clear that we had reached the financial basis for the development of the new generation of prototypes, we were able to put our full focus on the concrete plans for 2020. A huge thank you again to all the supporters who made this possible.

“We actually had to get all the engineers back into the development team and we had to re-form ourselves as a team in the vehicle development department.”

This means that after the extension of the campaign, you had to discuss the timetable and the goals for 2020 in detail again. Did this lead to a delay in the timing of the new prototype generation? Is it possible to make a concrete prognosis there?

Correct, we have extended the campaign by four weeks. In vehicle development, the entire team was only available to us about five to six weeks later. The same applies to the budget to really start all necessary projects and kick-offs. This means that we could only start a little later than originally planned. Our goal is now to make up for this delay in the projects. But, of course, none of us can say today how long the restrictions for protection against the corona pandemic will remain in effect, and what this could mean for our plans.

The development team is now again formed and the necessary resources are available. What exactly has happened on the strategic side in the meantime?

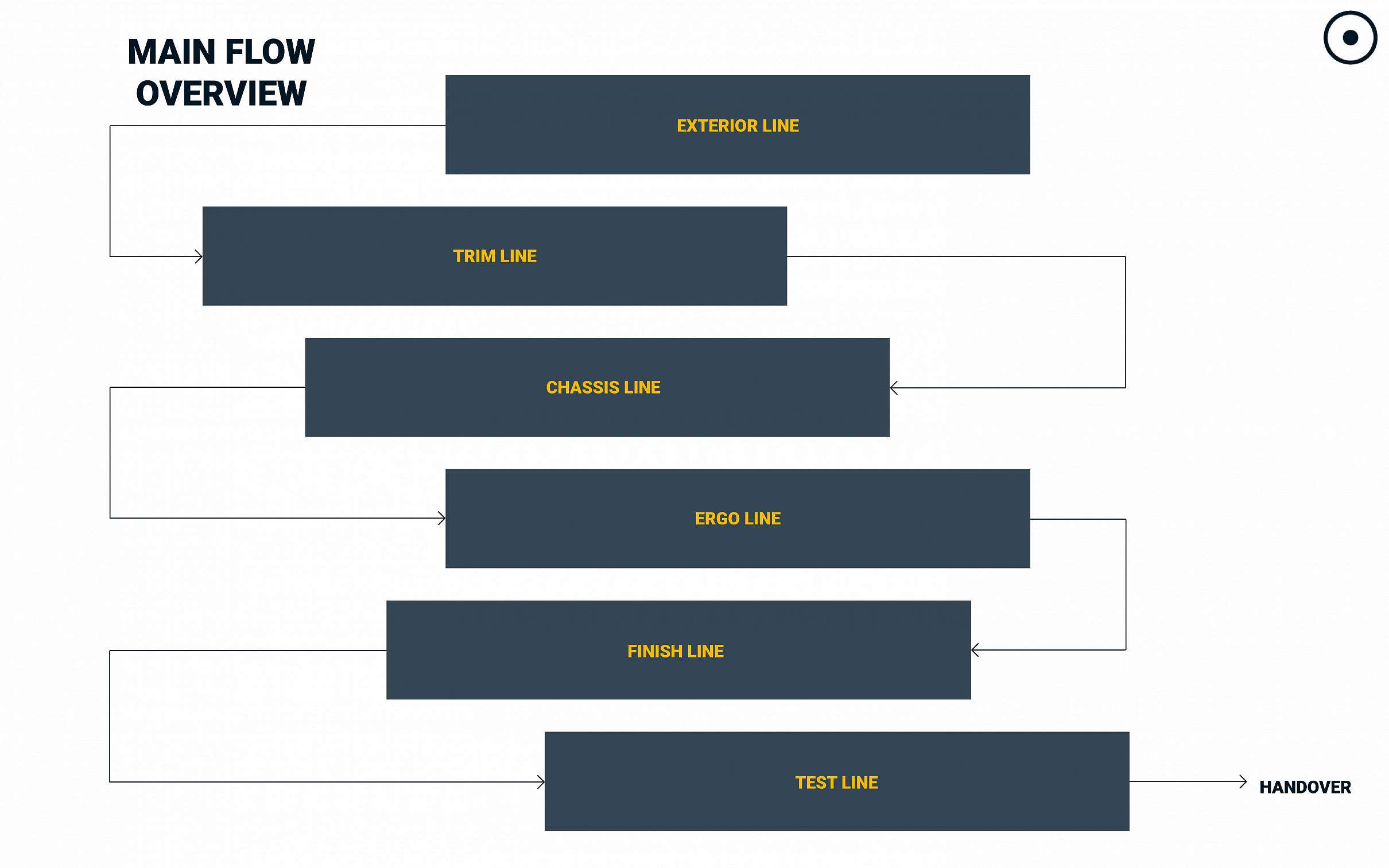

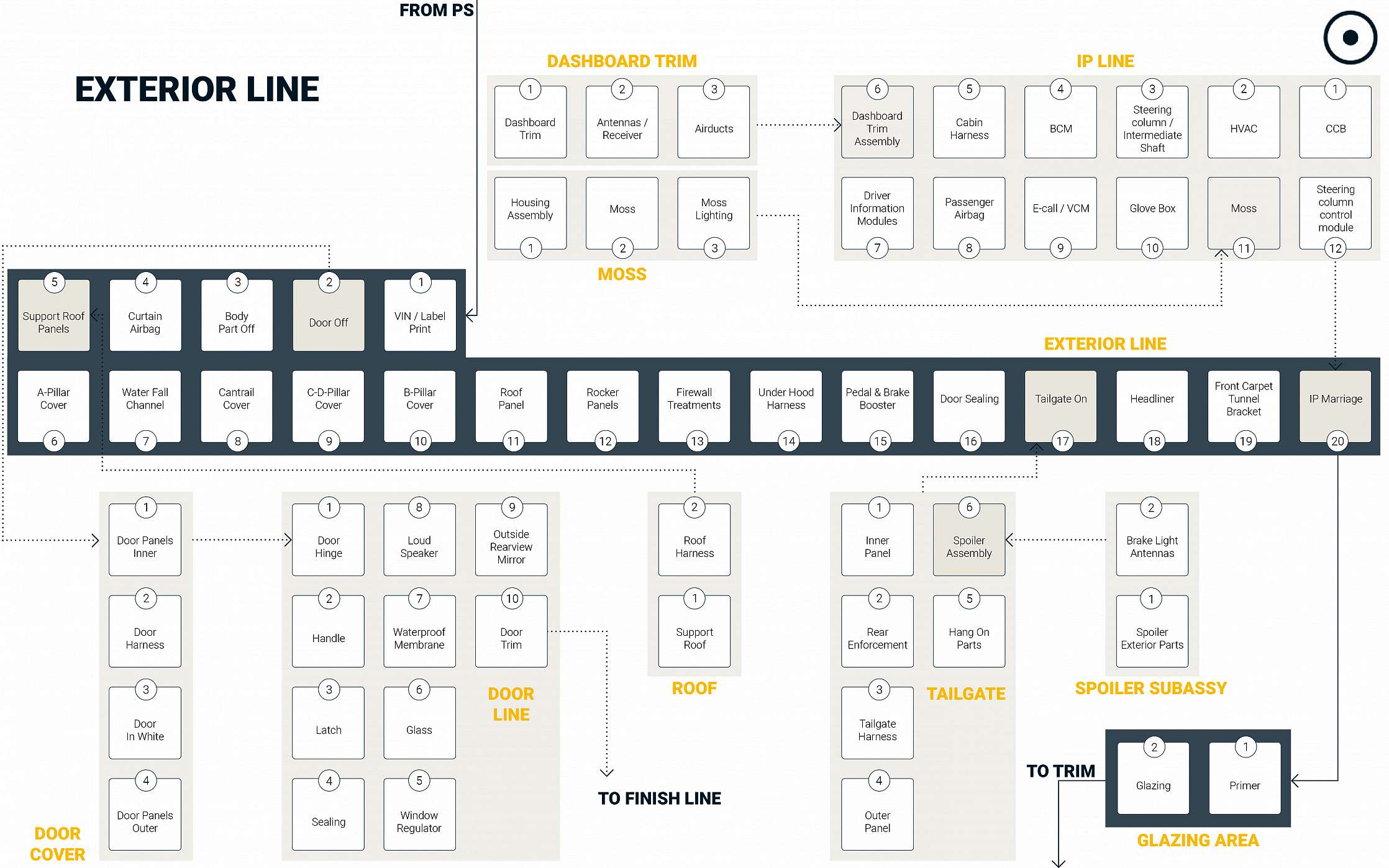

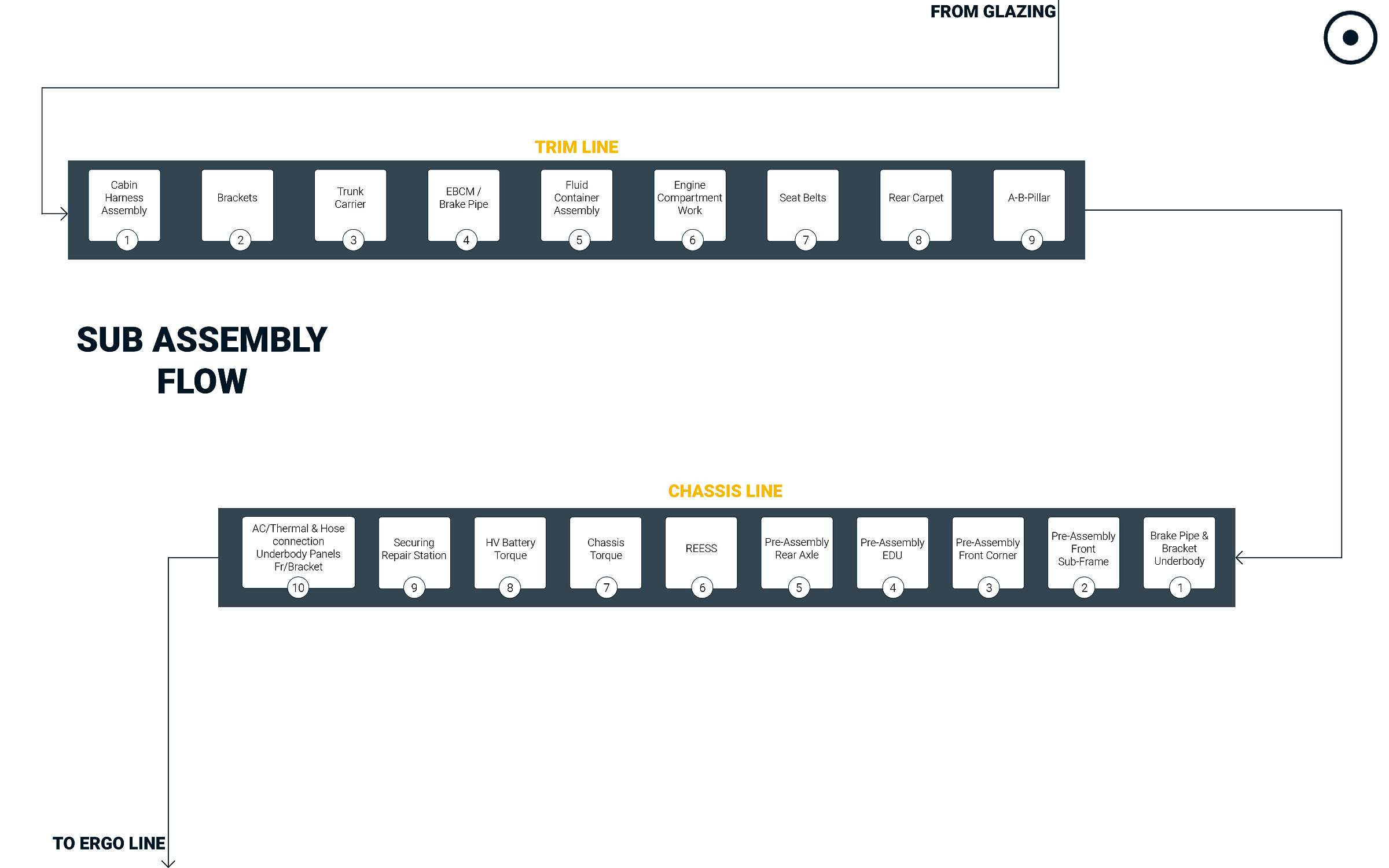

For me, strategy always means defining goals, i.e. determining the "what" and the "why". After that we work out in detail "how" we want to achieve the set goals. Therefore, we defined appropriate measures internally and discussed them intensively with our external partners in the last weeks. Our strategy in vehicle development is based on three pillars, namely progress in virtual series development, the construction of test benches, and the next stage of prototype construction, which has already been announced.

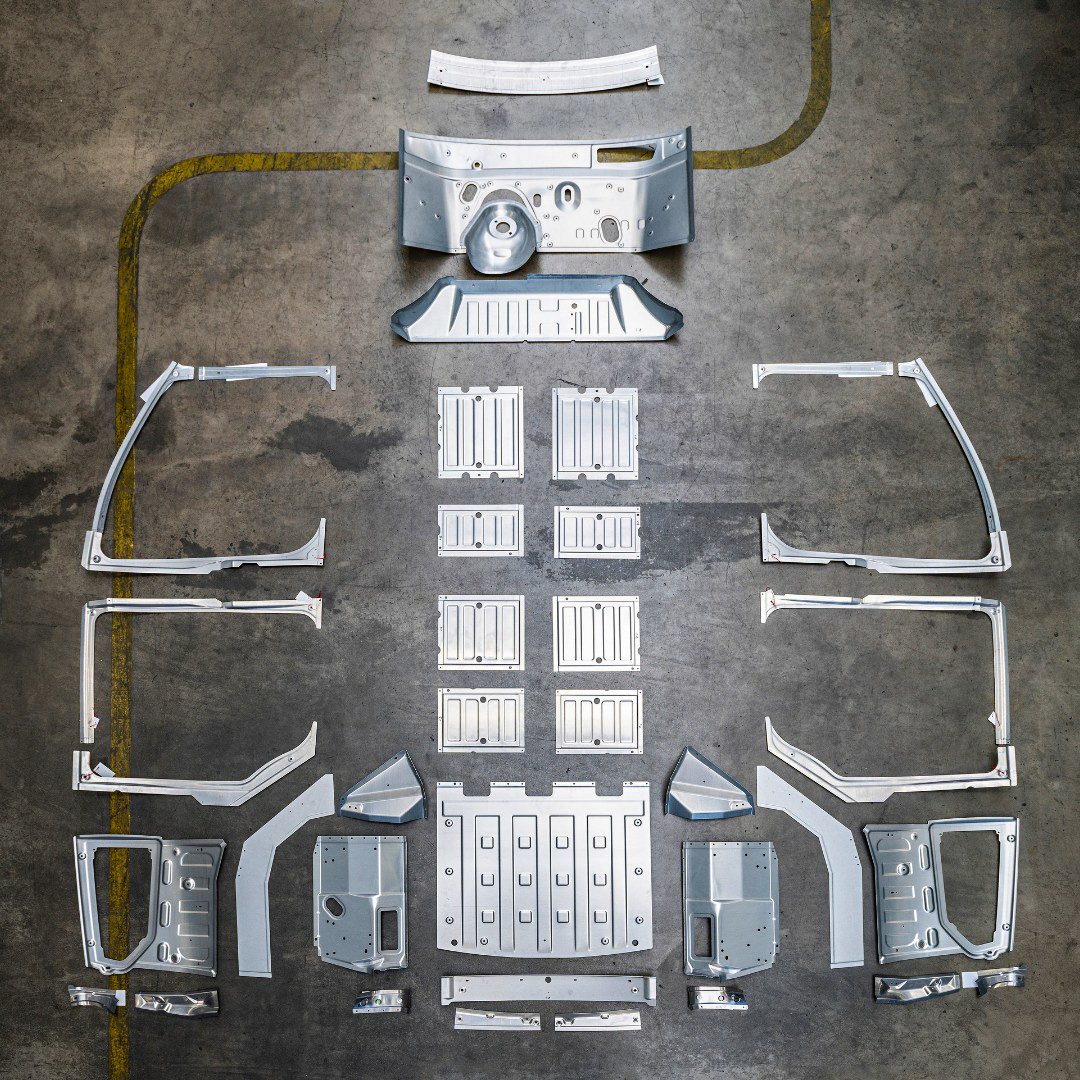

Very exciting! Let's talk about the construction of the new prototypes right away. Can you explain how such a prototype is built? The production methods that are used for the prototype build, for example, clearly differ from the ones applied for series production, is that correct?

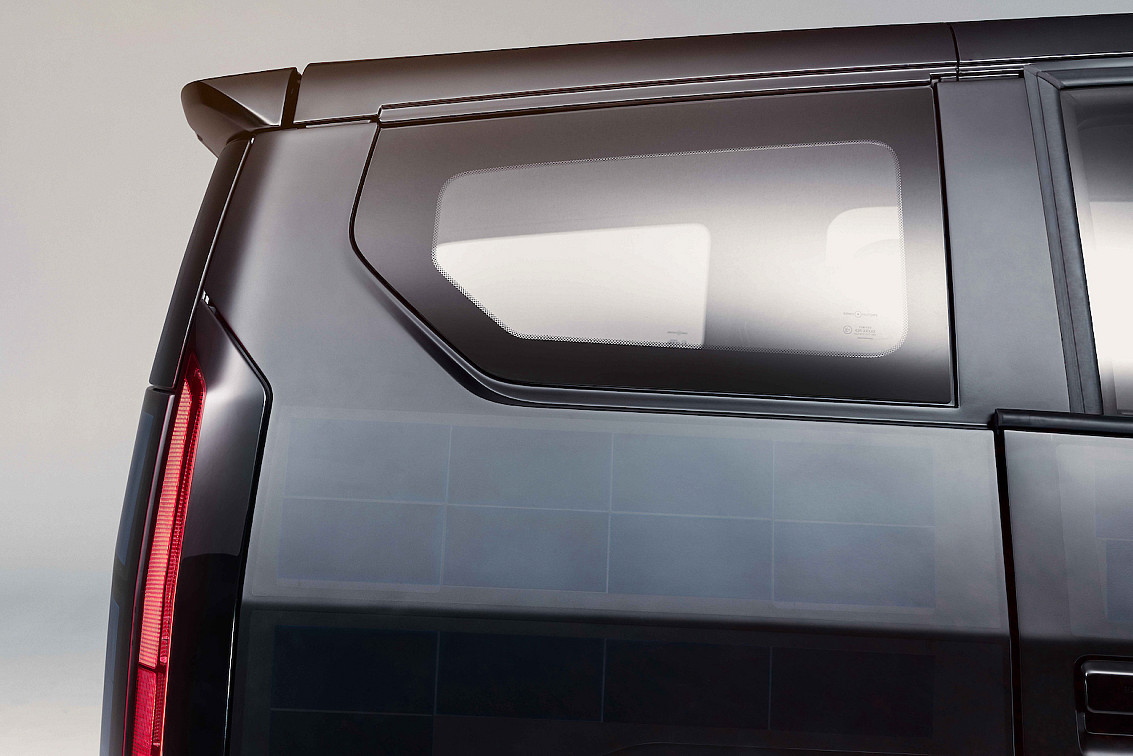

That is correct. One reason for this is that we only build a small number of prototypes. That means that other production methods and tools are used, for example for the trim components of the vehicles. On the other hand, the delivery times of some series tools take over 30 weeks. However, this does not mean that these prototypes differ greatly from the later series product in terms of appearance and function. Only the manufacturing method is different.

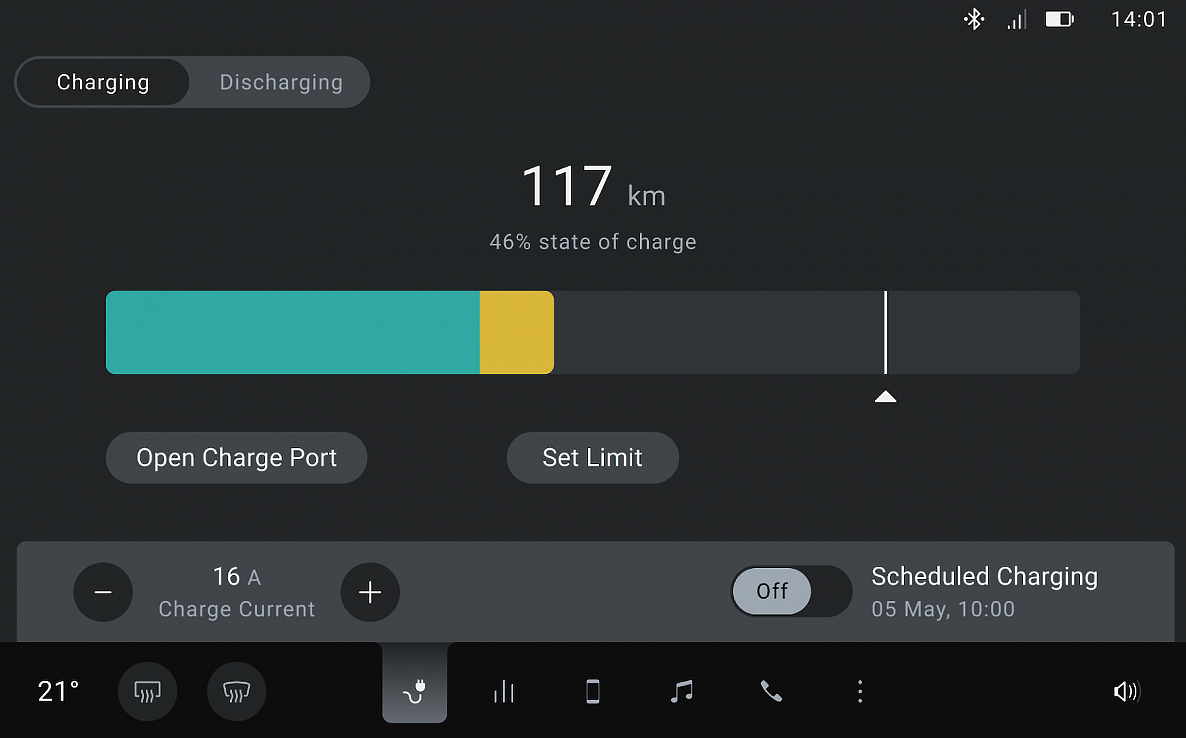

And what does this mean for the technical features of the Sion, especially the solar integration or the technology of bidirectional charging?

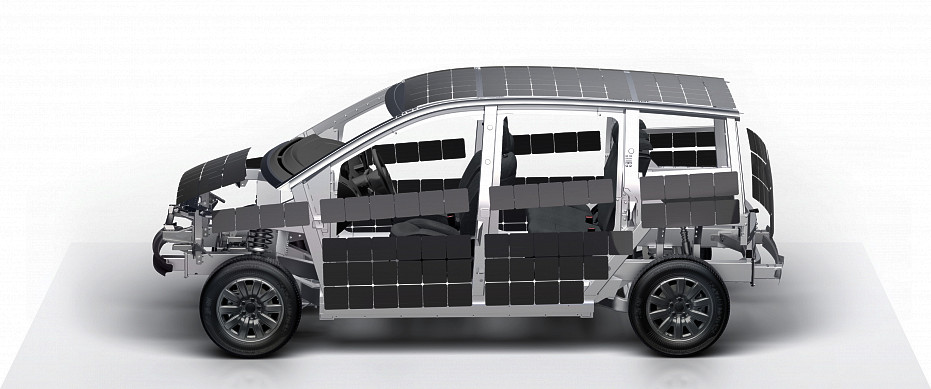

Every development goes through various stages of maturity and is carried out in so-called sample phases, which primarily define the software status and the production method of individual components. In our current prototypes, the vehicles that we have presented on our test drives, mostly A-samples, or concept components, have been used, i.e. components with a rather low degree of maturity. In the new generation of prototypes we can mostly look forward to B-samples. This means that the functionality, i.e. the software and the form of the components are already a great deal closer to the later series product. In the subsequent prototype generation, which we will build next year, C- and D-samples will already be used.

These prototypes are also developed with the aim of being presented to the community. But their development is also relevant from a technical point of view. Can you explain what functions they actually fulfill?

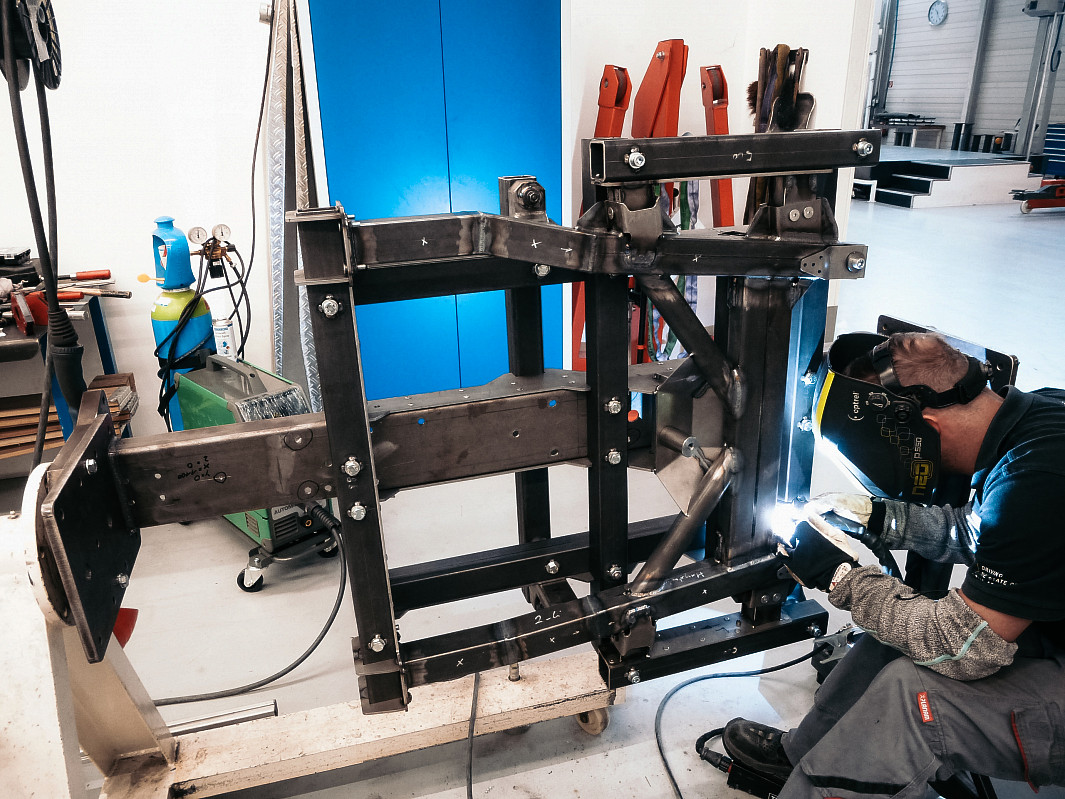

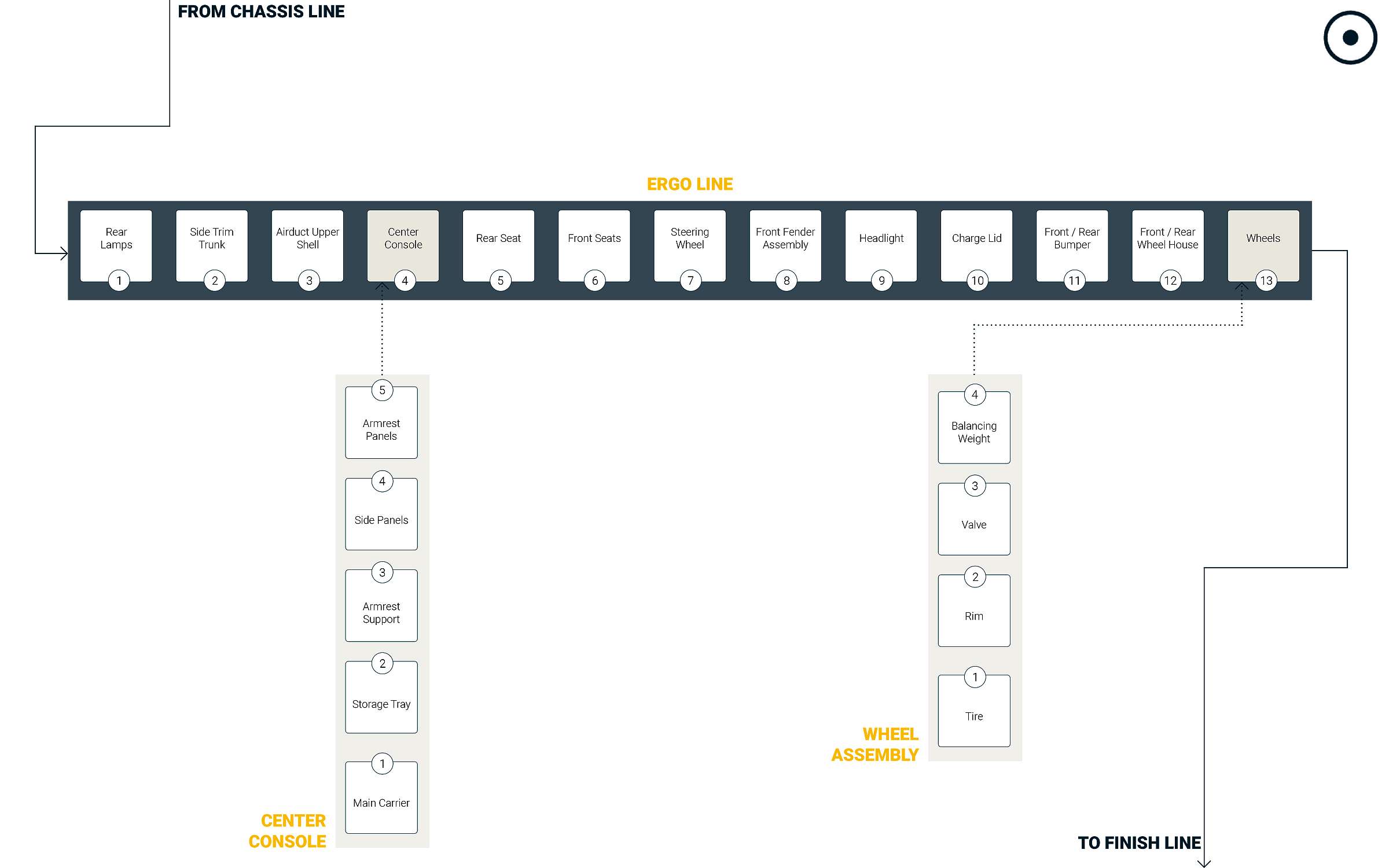

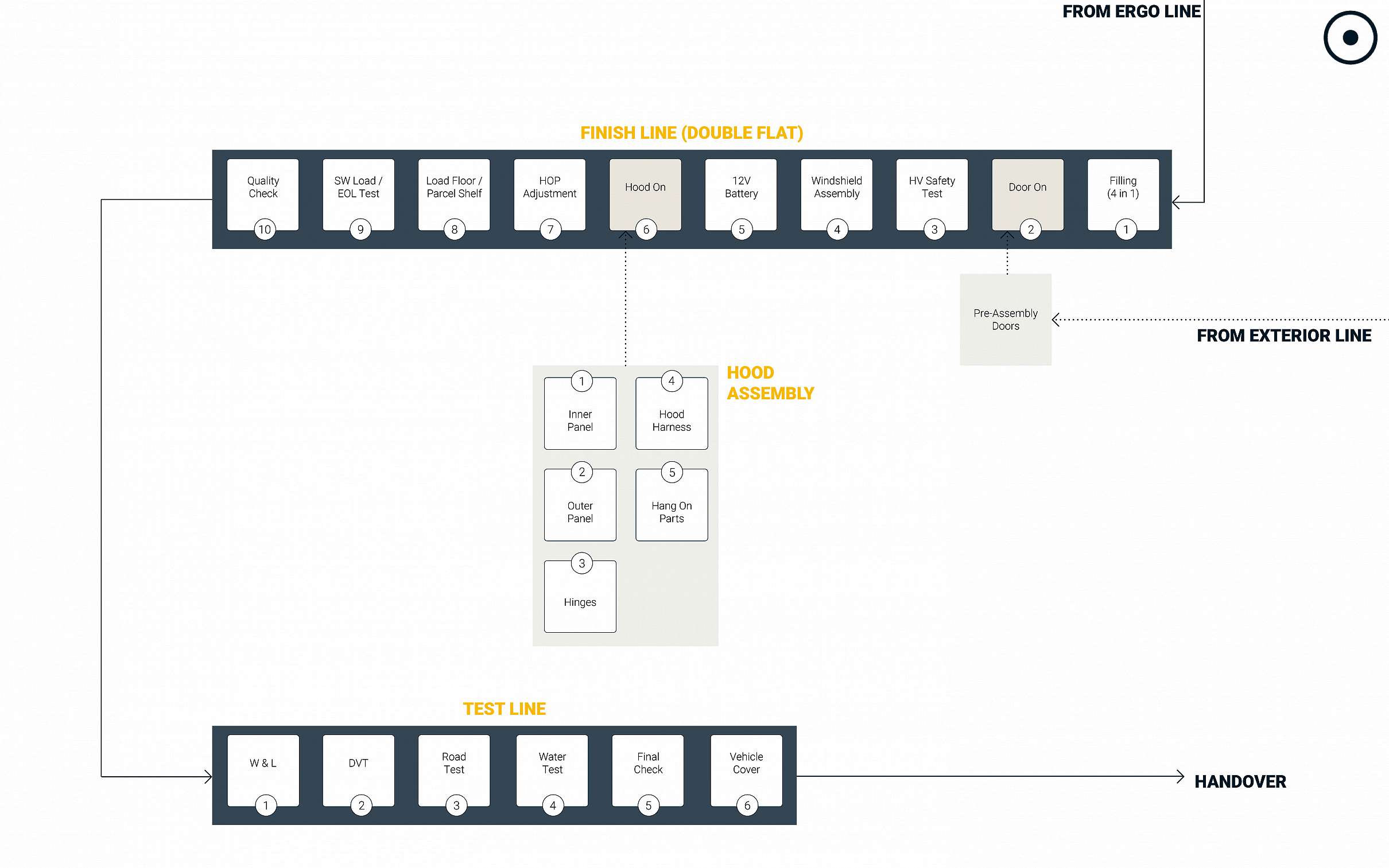

Basically, you learn an enormous amount in each phase of the vehicle development, which is why each individual phase is so important. Especially when working with the entire project team. You could describe the construction of the new prototype generation as a kind of test run. All of the departments that will also be working together on the construction of the series vehicle are involved – from purchasing to logistics, to production. Close cooperation with our prototype builder is also crucial in this phase. So we can learn above all to optimize our coordination processes, but we can also gain important insights into the integration of individual components into the overall vehicle. After all, one of the greatest challenges in vehicle construction is bringing together the various areas and components into one product; this is how this step in the production process is described.

And why is this important for your team now? Isn't the interaction of individual vehicle components already being tested on the virtual vehicle?

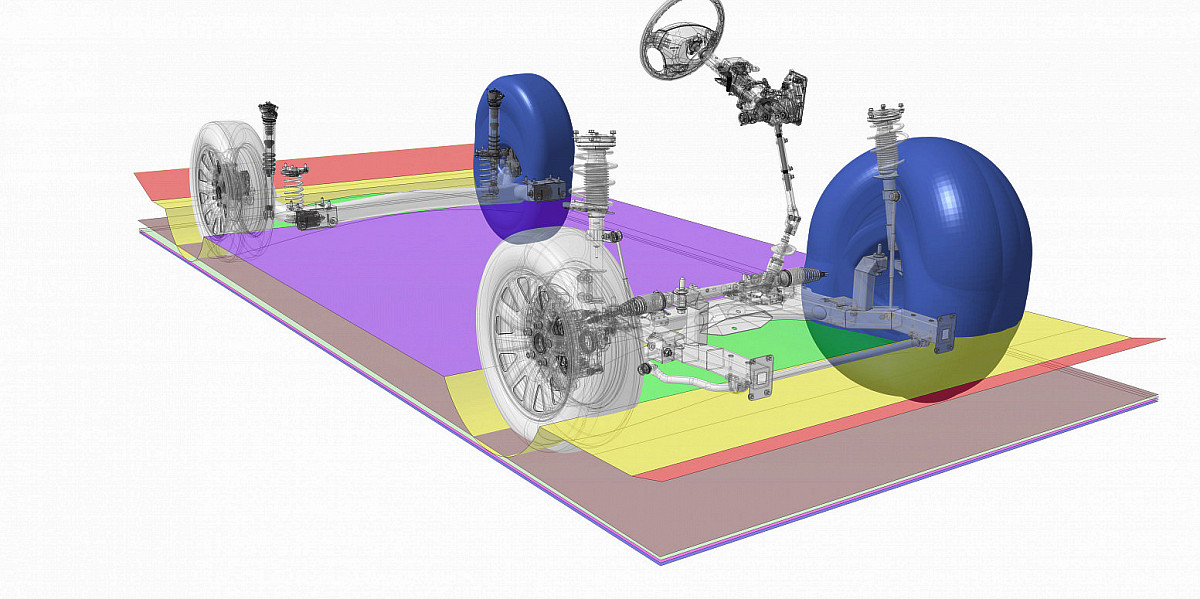

The biggest challenge for every vehicle manufacturer is that in the vehicle and in the vehicle system, no component, not a single part can function in any way on its own or change without affecting all other areas. The complexity, and thus the challenge, lies obviously in the interdisciplinary interaction of all vehicle areas. Of course, this can also be adequately developed and tested on the virtual vehicle. However, it is still necessary to keep track of the development status at certain points in time and validate it by building hardware, i.e. real components. Commonly named test benches are suitable for testing vehicle systems, for tests in the vehicle environment, we build prototypes.

In general, vehicle development requires increasingly flexible adaptation possibilities. We are responding to this by constantly improving our processes and, since the beginning of this year, we have switched even more strongly to an agile and lean working method. The modules in vehicle construction are grouped according to their functionality and cooperation. As project managers, we work with these groups on an interdisciplinary basis with regard to the entire vehicle in order to optimize cooperation between teams and thus, make it even more efficient.

Would you say that the way the Sion development team works is different from the way classic OEMs work?

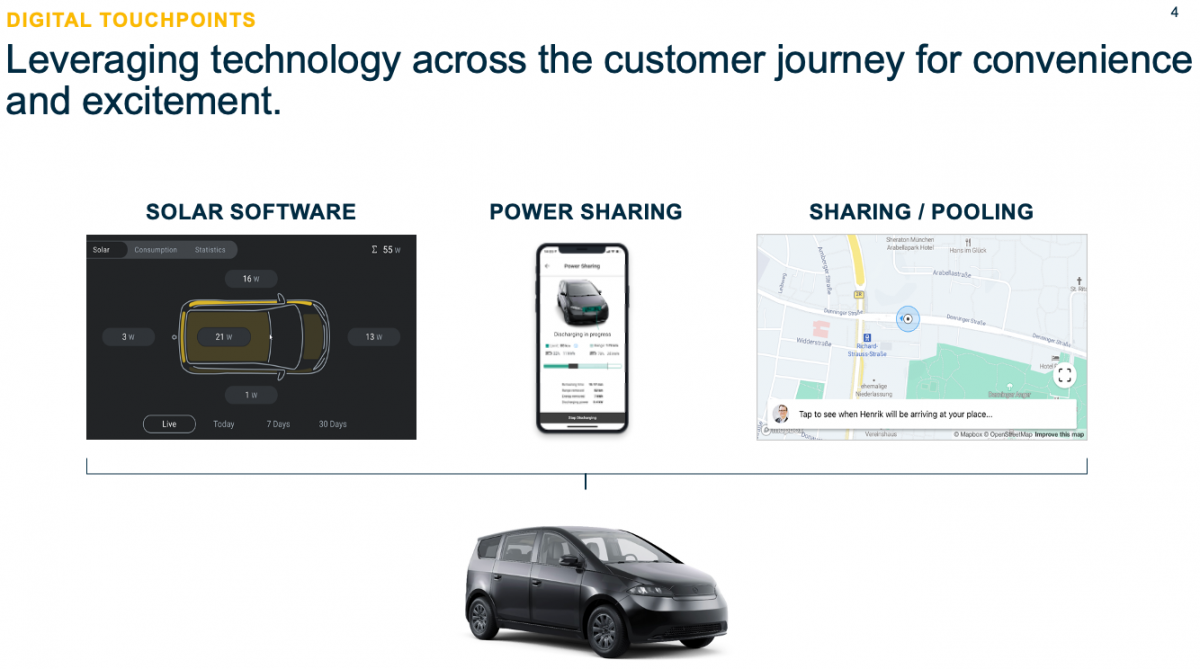

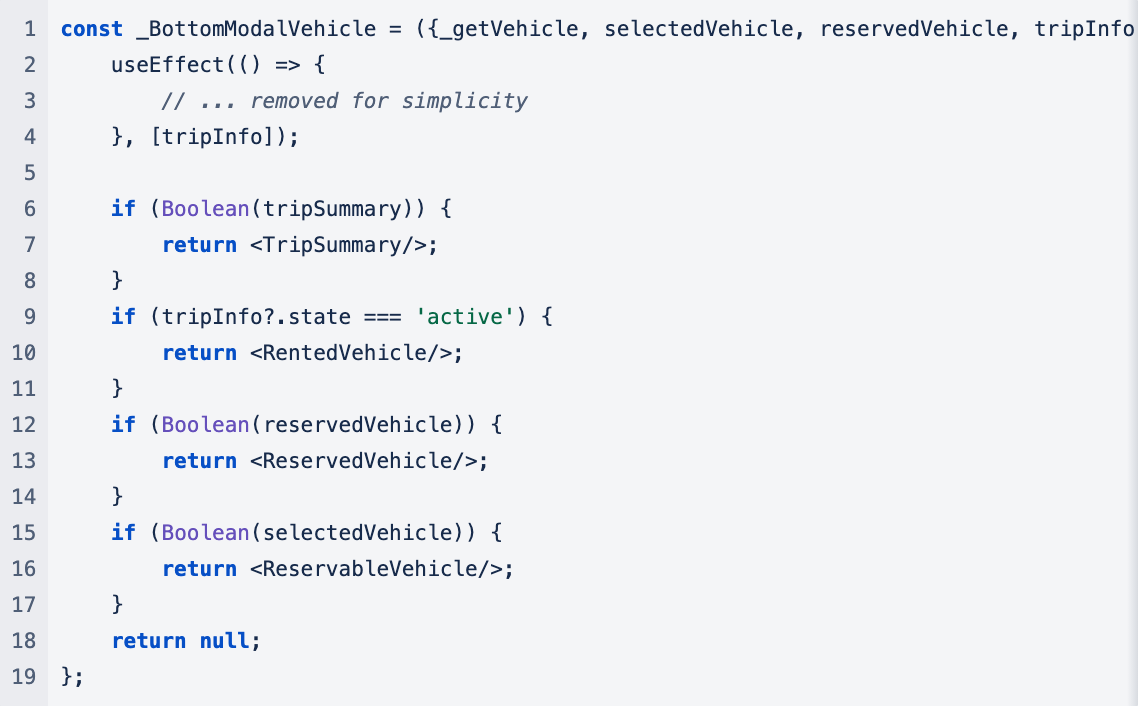

What certainly distinguishes us is that, on one hand, we have a particularly high proportion of software development due to the integration of sharing services in vehicle development; for this reason alone, we have to work in an agile manner. On the other hand, vehicle development requires synchronization points or milestones at which all development areas reach a certain level of development simultaneously. One such milestone is, for example, the design release.

This is when the procurement of components begins. We will continue to need these synchronization points in cooperation with our partners because in the automotive world, work is still not moving quickly and easily. What we have changed for us above all is that we have switched to hybrid project management. In principle, this means that we combine the advantages of classic project management, i.e. the organization of a process in sequential successive project phases and the waterfall model, with agile working methods such as SCRUM.

Earlier you spoke of the three pillars of the next development stages. Could you explain them in more detail?

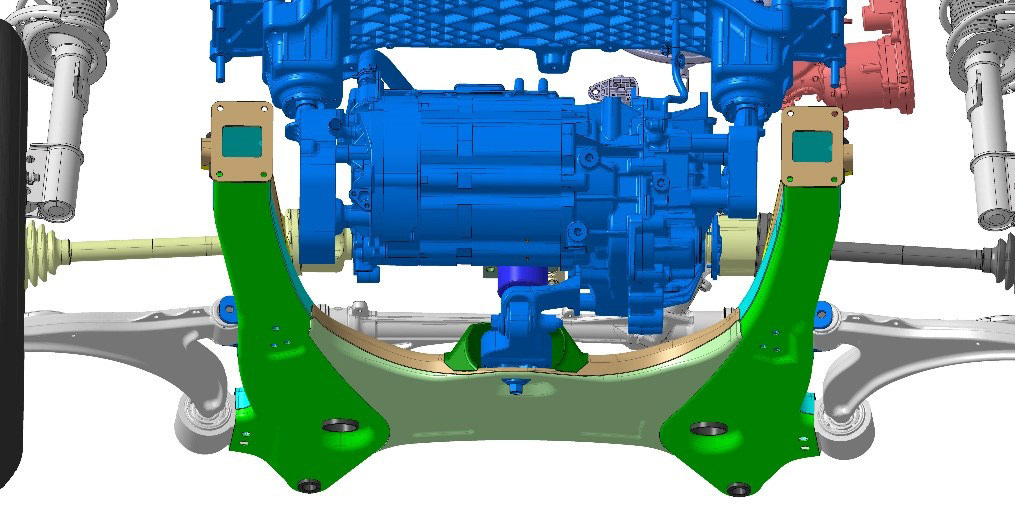

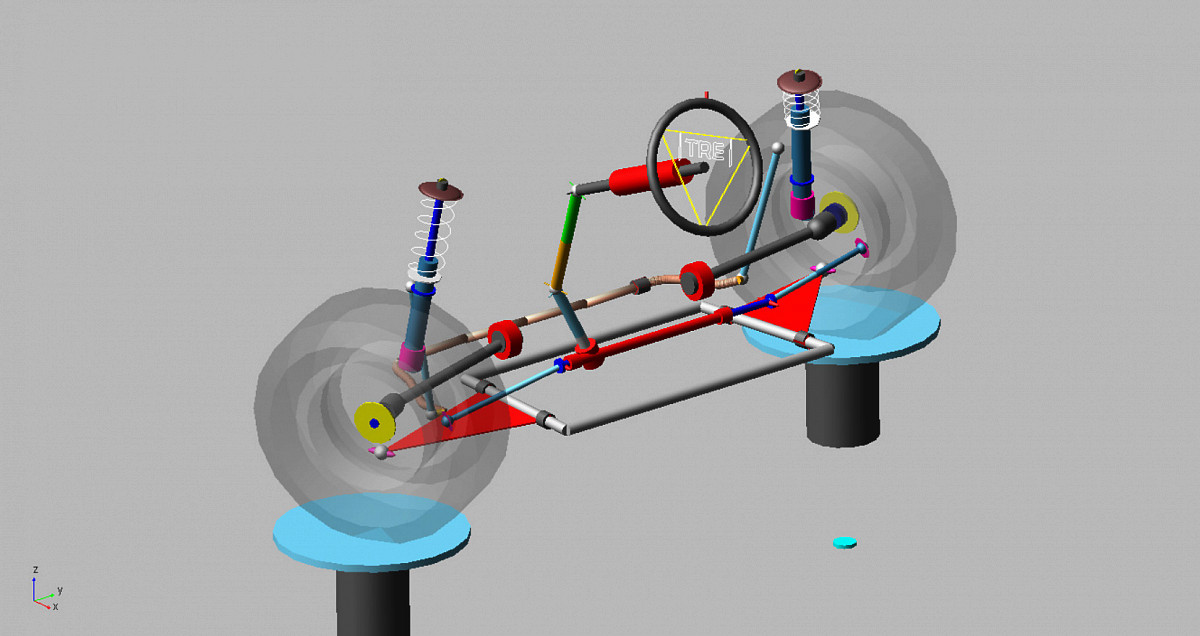

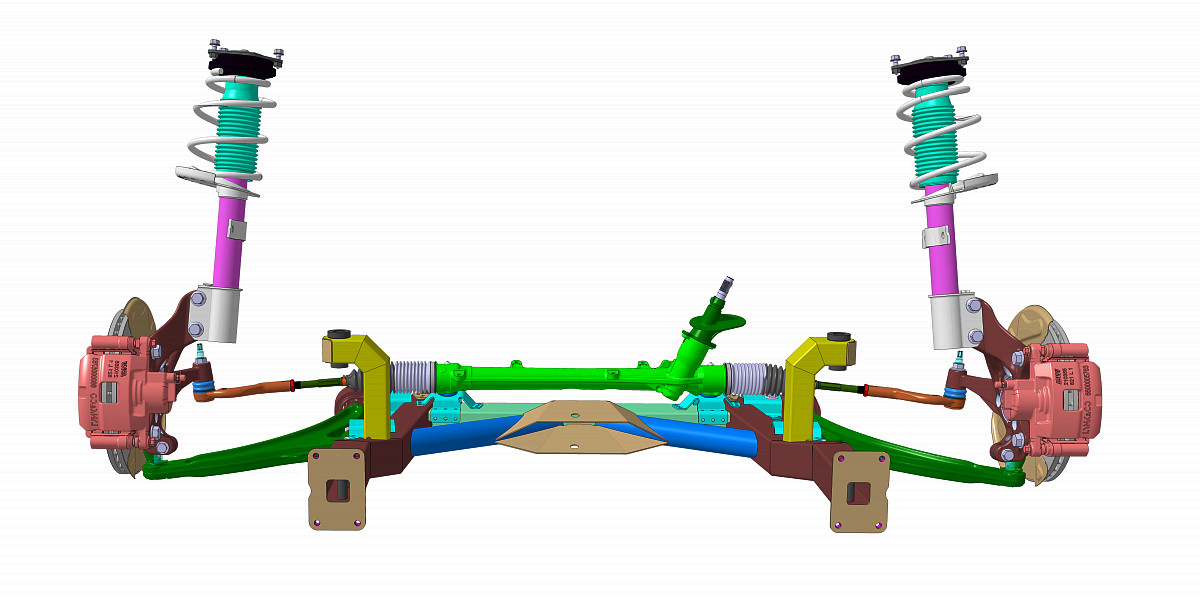

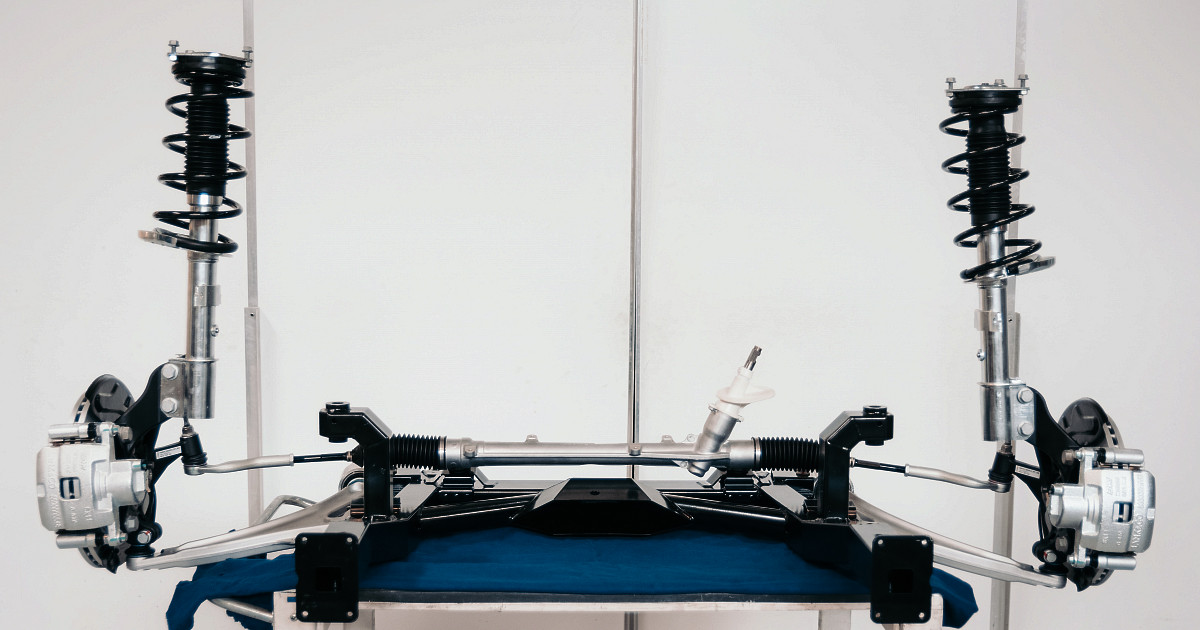

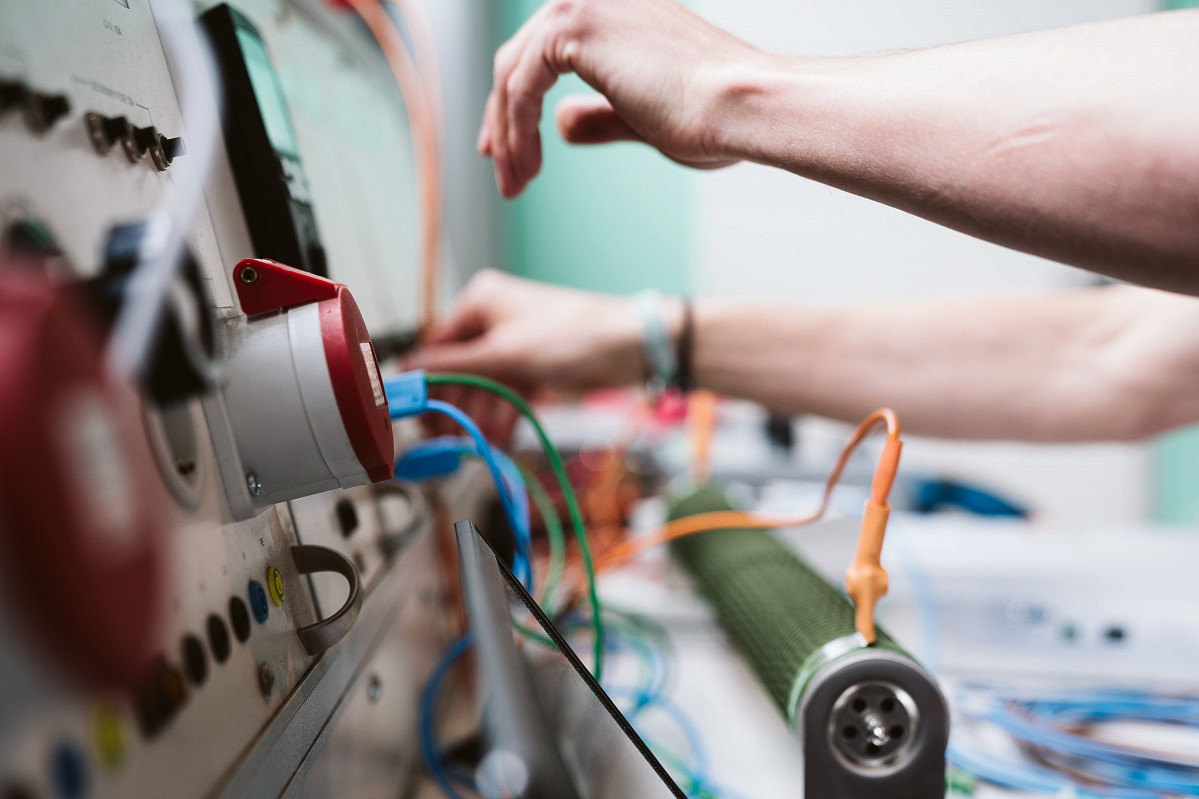

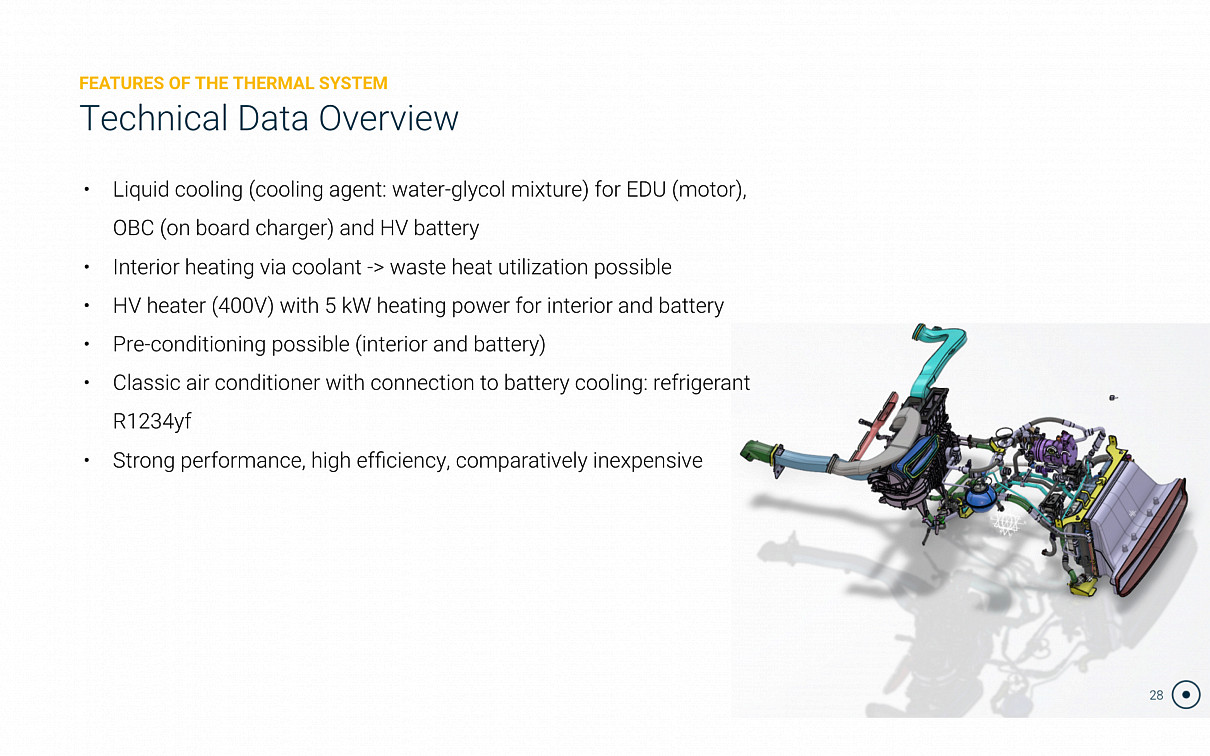

Of course. The first pillar is the virtual series development. Here, we work together with all our series partners on the construction (CAD; computer-aided design) and simulation using computer-aided engineering (CAE), or in simple terms, the virtual validation of our vehicle. The second pillar is the construction of the prototypes, which we will produce this year together with a prototype builder in order to carry out further tests. The third pillar is the construction of various test benches for the areas of powertrain, electrics and electronics (E/E), thermal and infotainment. All serial parts will be put into operation on a workbench there. The advantage of this is that we can already test the functionality and communication of the individual vehicle parts quickly and cost-effectively in the subsequent vehicle environment.

Powertrain and E/E: These terms are certainly new to a lot of people. Can you briefly explain which components will be tested there?

On the E/E Bench primarily the components from the low-voltage vehicle electrical system are tested. These are, for example, the control units of the window lifters, wipers, lights, or the eCall function. On the powertrain bench, the powertrain components are tested, for example the engine, the battery, and the bidirectional charger.

Why did we choose these four benches in the first instance?

This selection allows us to test all the important and critical systems in parallel with the virtual development directly at our site and ensure that all components interact with each other as planned. By the way, it's also a lot of fun.

I'm sure it is! Can you now give us a personal insight into the life of a developer? You have already accompanied the construction of the first prototype generation. Can you tell us what the difference is between then and now is? Back then, you were a very small team. What are you particularly looking forward to, what challenges do you expect?

What everyone is most looking forward to, and what delights every developer the most, is the phase in which that, what has been developed virtually so far, is finally put together and begins to exist physically. When I look back on the construction of our current prototypes, the greatest thing was the cooperation within the team and with the prototype builder, but also how motivated we were despite how stressful and hectic it felt. Being on-site, seeing how the vehicle is built piece by piece from the body to the installation of the solar panels and then in the assembly – that was simply indescribable. I am, again, most looking forward to seeing what we have conceived, planned, and developed standing before us in reality. And one of the absolute greatest moments for us will be when we can present the vehicles to the community.

“What delights every developer the most, is the phase in which that, what has been developed virtually so far, is finally put together and begins to exist physically.”

So you will be closely involved with the construction again?

Max: Yes, of course. This is an enormously important phase. Especially in the crucial last weeks we will be on-site non-stop to learn and document as much as possible from this phase. I am even looking forward to working through the night when the final phase is about to start, to stand there until 5 o'clock in the morning assembling the car.

What particular challenge or difficulty do you remember?

To be honest, I have only positive memories of building the first prototypes. Something we should not repeat, however: the last time, the car was completed the night before the release event. Due to small beauty corrections, we took the dashboard apart, because we thought the moss was not optimally illuminated. This caused a short circuit and at five o'clock in the morning we had to disassemble the whole instrument panel again to put in a new cable. That's when you reach your limits.

Last but not least: Maybe you can tell us how the cooperation with the suppliers and our partners we will build the new prototypes with looks like?

After the end of the campaign it was important to reactivate all partners as quickly as possible, to get new offers and to negotiate, in order to then go into the kick-offs accordingly. Our partners also followed the Community Funding Campaign closely and joined in the excitement. Now they are all trying to adjust their capacities as quickly as possible and start working with us on the project. Like last time, a prototype builder will then build the vehicle for us at their location. We will then work side by side with this partner.

There is one question I still have to ask. Who will be the partner who builds the new Sion prototype?

I knew this question was coming (smiles). Currently we are still in the final coordination rounds before we make a final decision with which partner we will join in these next steps.

So is this the cliffhanger?

This is the famous cliffhanger (laughs).

]]>

]]>

]]>

]]>

]]>