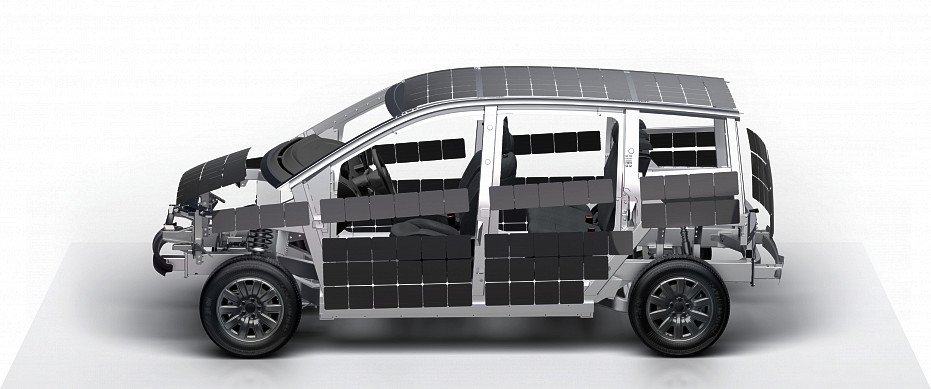

How do you integrate solar cells into an electric car? A simple question that requires complex solutions. Especially when the solar cells do not only cover the roof but also the rear, the doors, the fenders, and the hood. Our expert for photovoltaic power electronics, Christian, will tell you what kind of technical challenges the integration implies and why we had to develop a completely new type of voltage converter.

To someone who is not an expert in the field, integrating solar cells into a vehicle, seems pretty simple: Just put solar modules on it, connect them to the battery, done. This may not sound very complicated, but in practice, it is very complex. Especially if you integrate photovoltaic cells not only at one but several points on the vehicle body. Mastering this task requires a high level of expertise in a variety of areas, such as photovoltaics, electrical engineering, and vehicle design. We have combined all these skills in our team to develop the most efficient solution for the Sion.

Together with our partners, we have not only developed our own, completely new technology for the integration of the cells, but also a device that makes the use of solar power possible in the first place. We call this device the “MPPT Central Unit”. MPPT stands for Maximum Power Point Tracking, a procedure commonly used in photovoltaics.

To realize the solar integration for the Sion, we had to rethink everything. Developing the Solar Integration, we had to ensure that all vehicle components are optimally prepared for the integration of the solar components. One thing's for sure: The Sion has been developed as a solar vehicle. Every decision in vehicle development, no matter how trivial it may seem, is always made by us concerning the efficiency of the photovoltaic system.

Optimized Performance For Each Cell

Maximum Power Point Tracking plays an important role here. This process adjusts the electrical load on a solar module so that the cells can deliver their optimum performance. Not every cell generates the same amount of power, because our energy supplier, the sun, moves constantly. Furthermore, not all solar cells on the Sion point in the same direction.

This means, for example, that the strength of the irradiation and the temperature on the photovoltaic modules change. Thus, before the electricity generated can be fed into the battery, some electrical adjustments have to be made – and that's where the MPPT Central Unit comes in.

There are different steps involved in the conversion of voltage. First, the MPPT Central Unit combines the different module voltages to a common level below 60 volts. Only then the conversion to the voltage of the high-voltage battery takes place. This is between 300 and 400 volts.

As with any conversion of power, electrical losses occur during this process. Our task was to find out how efficient the conversion of different voltage levels is and how we can optimize it. After all, one question is of high importance: How much electricity generated in the cells finally reaches the battery?

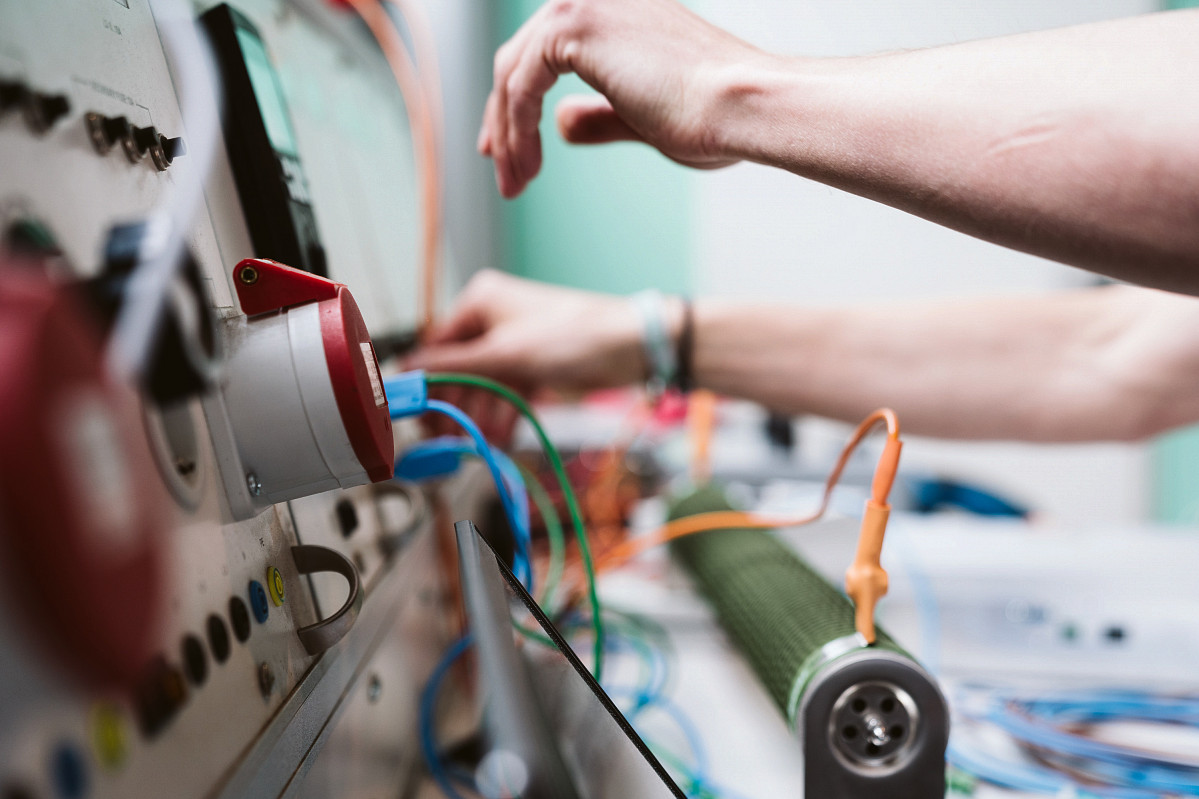

Developing solar modules for the integration into a vehicle is one thing, but adjusting them optimally on the vehicle and providing the power for the battery and propulsion is the real challenge. Earlier this year, we were able to test the prototype of the device, which Sono Motors is developing precisely for this task.

Combining Expertise

The MPPT Central Unit has been developed in very close cooperation with selected partners. To ensure that everything is perfectly matched to the application purpose in the vehicle, one of the most important tasks was to design the suitable electronic architecture for the device, check the circuit diagrams and select suitable components that are approved for use in road vehicles. Also, the interfaces to the other devices, for example the battery, must be precisely defined and tested.

The successful design and integration within the vehicle is a task that particularly drives our team since Sono Motors is the first company to establish such a solar converter not only for research purposes but also for use in a production vehicle.

To make such a project a success, not only the expertise within our team is needed, but also competent partners. The company Tecnalia from Bilbao, Spain, is one of them. The private research institute is one of the largest facilities of its kind in the field of renewable energies and supports us especially in developing and testing the MPPT Central Unit. The team on site works together with our engineers enthusiastically on the project. The results so far, speak for their years of expertise. The successful test phase of the prototype already makes us very confident that we will achieve the goals we have set ourselves.

The first test results have even exceeded our expectations. This applies especially to the converter efficiency. It describes the ratio of the achievable output to input power and is thus a measure of the losses incurred. The average value of 94 percent achieved in our first tests over various scenarios is already top level. We are confident that we can achieve even better results with a little more fine-tuning.

Maximum Power from the Solar Modules to the Battery

The integration of solar cells has an impact on every area of vehicle development. Especially vehicle design and solar integration must be closely coordinated. A good example are door handles: How exactly do they have to be placed on the car body so that the solar modules can be ideally integrated? If one parameter changes here, the entire power calculation changes, including the voltage levels that the MPPT Central Unit has to convert. Internally, continuous coordination between engineers and designers is therefore necessary.

456 half cells are seamlessly integrated into the body of the Sion.

We have put together a dedicated VIPV (Vehicle-Integrated Photovoltaics) team for this purpose, headed by our Director of Photovoltaic Integration Mathieu Baudrit. Within this team, we coordinate every development decision and its effects on photovoltaic integration, including, for example, the cabling of vehicle components. Therefore the complete transmission line from the solar panels to the battery must be trimmed for maximum efficiency.

The more the battery is charged with solar power, the more efficient is the overall system. That is why the Sion always charges, standing or driving, and even in diffuse light. The MPPT Central Unit is wired in such a way that the solar power can be directly used for the engine and auxiliary units. The solar cells, therefore, support the Sion's propulsion directly with energy from the sun.

Further Testing for Optimized Performance

The first development stage of the MPPT Central Unit has been completed. We will optimize the electrical architecture and mechanical design of the device in the next weeks and months. Further tests with regard to electromagnetic compatibility are now also important, that means determining the emission of unintended signals on the one hand and resistance to external influences on the other.

We will also expose the MPPT Central Unit to high ambient temperatures over a long period of time under full load to see how it performs. This will help us identify those component temperatures that the vehicle system needs to constantly closely monitor in order to ensure the safe and efficient operation of the unit for many years to come.

As soon as the current situation due to the coronavirus allows, we will also expand our test benches at our Munich site. We will then be able to use PV simulators to examine the behavior of the solar cells at different temperatures and light incidence for the fine adjustment of the MPPT Central Unit. Our entire team is already looking forward to the next steps.

The further development of the benches, the production of the new prototypes – this year will be exciting and extremely busy for all of us, but we are getting closer and closer towards our goal. With our Solar Integration we are developing a climate-friendly charging solution that has the potential to completely change the market in the long term.